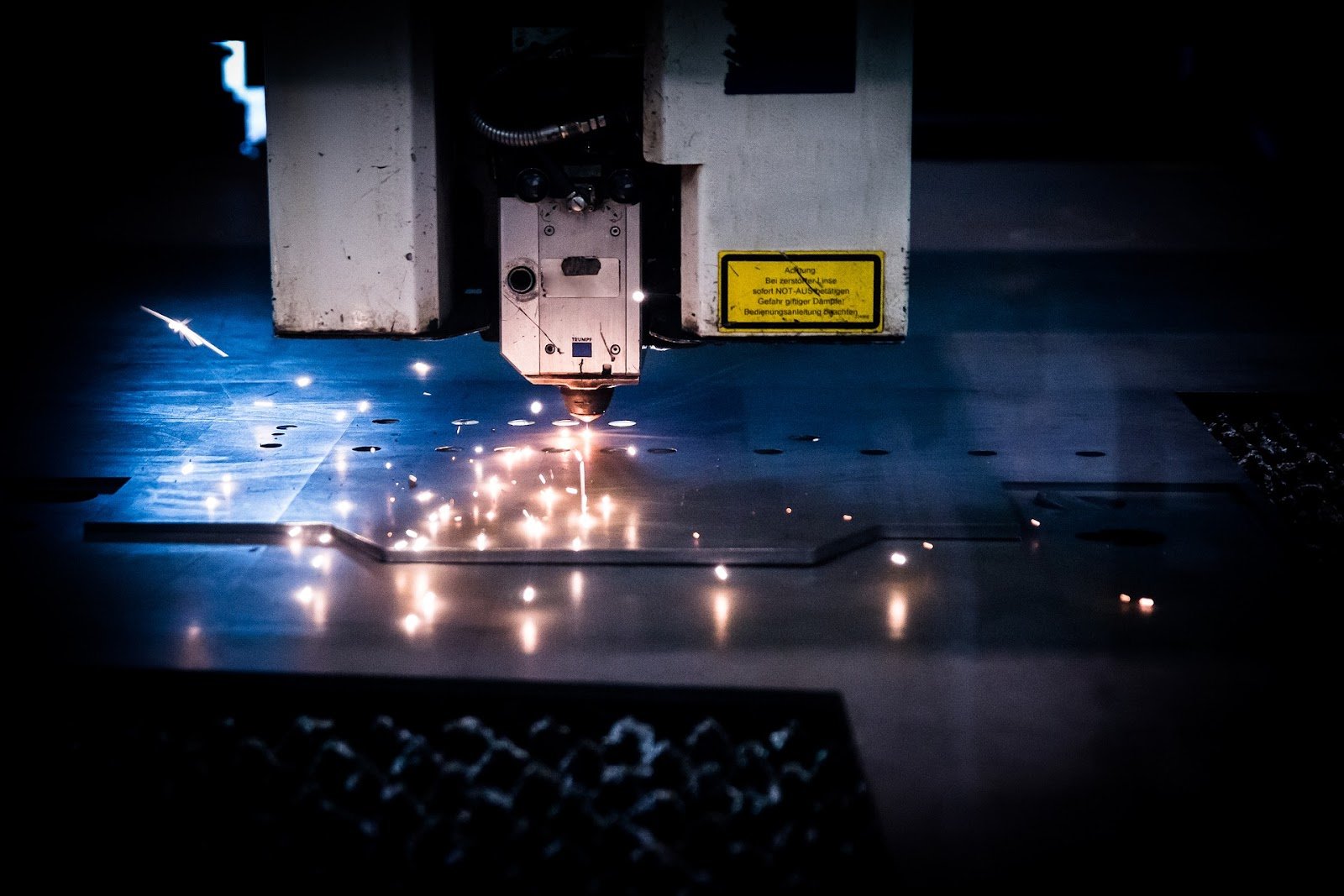

Coming in a broad spectrum of different sizes, shapes, speeds, functions, and other dimensions, CNC machines are indeed the workhorses of precision engineering and the global manufacturing industry.

These indispensable tooling systems located on your shop floor or at the premises of your CNC machining service partner have a wide variety of uses—from molding, drilling, or milling pretty straightforward objects from different materials to fabricating complex parts for the need of the automotive, healthcare, and the aerospace industries. Packed with varying degrees of automation and software, they are improving the efficiency of your manufacturing process and, ultimately, the final quality of your produced parts and components.

So, if you’re on the market for a new CNC machining setup that will drive your business to further success, the main challenge comes in picking the right CNC machine system that will accommodate your business’s needs and the needs of your clients. And how do you narrow down to the most critical factors with such a wide range of factors to consider? This article will lay out the four most important things to consider when selecting the correct CNC machining setup for your facility.

Review Your Existing Machine Set-Up And Operator Experience

To begin with, you will need to consider what the existing machine setup is like at your facility and the level of experience your operators and engineers have in using next-level CNC machining tools.

Suppose you do have an existing CNC machine in your production facility. In that case, you should evaluate if it’s still appropriate for your manufacturing purposes, understand where your current gaps are, assess your existing CNC machine life span, and assess the cost-effectiveness of replacing it with a new, higher-performing one.

In addition, the proficiency and expertise of your machine tool operators should also play a critical role when deciding what type of CNC machine to invest in next. In general, you should know that the new age’s more highly automated intelligent machines demand less human intervention than simpler machine setups with limited functions.

The Part Difficulty And Complexity You’re Trying To Achieve

Perhaps the biggest challenge with selecting the proper CNC machining setup for your company is to go with a setup that will be able to deliver the part difficulty, complexity, and precision that you want to manufacture and sell.

For instance, if you manufacture components and products for the medical, defense, automotive, or aerospace industries, you should know that they require having advanced CNC machine setups, where different spindles are selectable, capable of maneuvering, cutting, drilling, and shaping parts controlled through multiple axis.

Good examples of these CNC machines include machines with 3 to 6-axis machining centers and 2 to 8-axis turning centers. On the other hand, for standard parts and batch productions, you may consider either a milling machine with 3 to 6-axis or a vertical or horizontal CNC lathes with 2 to 5-axis.

The Materials That Are Going To Be Used

As you probably know, most CNC machining setups can work on nearly all existing materials, including copper, aluminum, steel, titanium, etc. Nevertheless, the type of materials that you’re going to use in your manufacturing process can significantly influence the machine design and spindle selection and affect the levels of durability, performance, load-bearing, and precision that can be achieved.

The materials’ physical properties and optimum cutting conditions should also influence the selection of machine tools capabilities like maximum spindle speed, peak spindle motor horsepower, and max spindle motor torque, among other things.

The Type Of CNC Control System

Last but not least, when selecting the appropriate new CNC setup for your needs, you also need to match your choice with the selection of the most practical CNC controlling system possible. The selection of your control system will depend not only on the levels of automation but also on the number of the axis to be controlled and the manual interventions needed during the production process.

For that reason, you should always go beyond just selecting the biggest and nicest looking screen for your CNC control and consider the following essential factors as well:

- The effectiveness of the control system;

- The reliability of the CNC controls;

- Software stability;

- Whether the system is user-friendly, as your operators are the ones who will need to work on the system and navigate through the different sets of commands that the system offers.

Final Thoughts

Selecting the proper CNC machining setup for your company is the foundation of a project’s success. For that reason, you should dedicate the time and effort to understand your future requirements and select your machine accordingly thoroughly. The “perfect fit” will allow your company to reach higher efficiency, enhanced accuracy, improved job quality, and greater profitability.